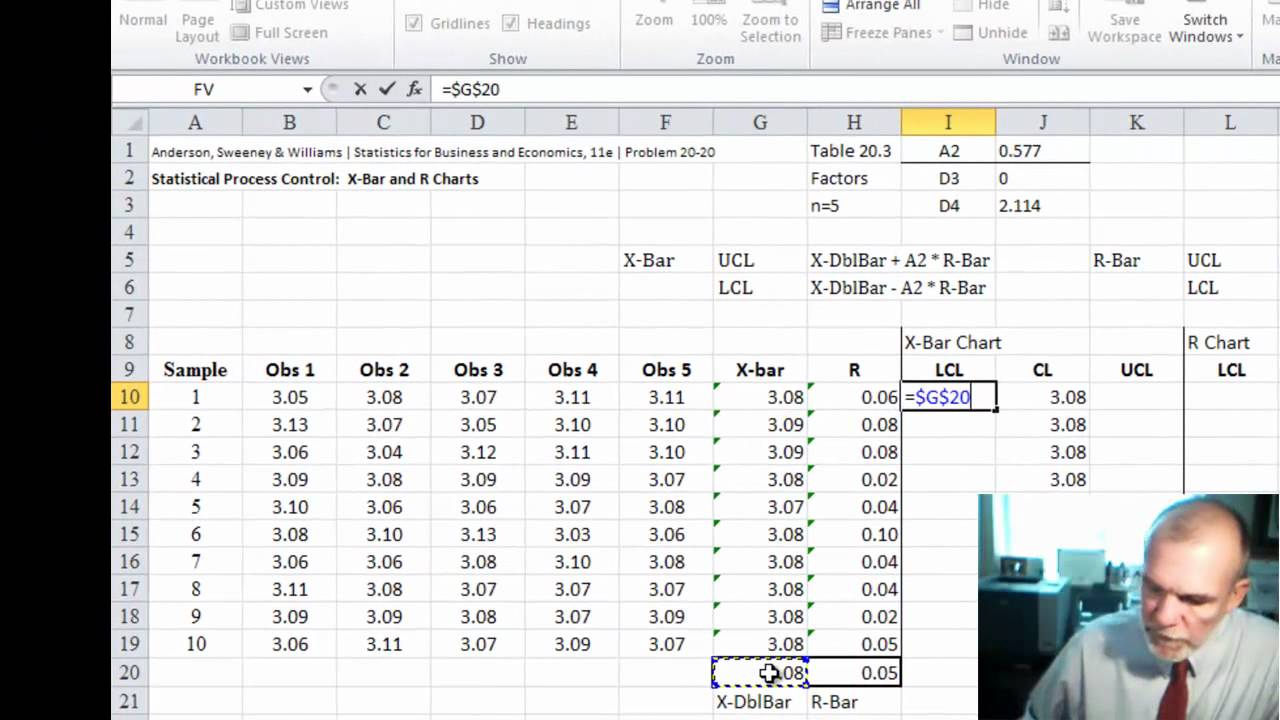

The cumulative sum ( CUSUM) and the exponentially weighted moving average ( EWMA) charts are also monitors the mean of the process, but the basic difference is unlike X bar chart they consider the previous value means at each point. These combination charts helps to understand the stability of processes and also detects the presence of special cause variation. It is actually a two plots to monitor the process mean and the process variation over the time and is an example of statistical process control. X bar R chart is used to monitor the process performance of a continuous data and the data to be collected in subgroups at a set time periods. Selection of appropriate control chart is very important in control charts mapping, otherwise ended up with inaccurate control limits for the data. Control charts can be used for far more than just checking the status of a process they are also used as an investigative monitoring tool to bring and test ideas to find solutions to problems in the operations.X Bar R charts are the widely used control chart for variable data to examine the process stability in many industries (like Hospital patients’ blood pressure over time, customer call handle time, length of the part in production process etc.,). SPC is applicable in a wide range of organizations and applications, including non-manufacturing. Many organizations implement SPC to satisfy customer requirements or to meet certification requirements. Often someone within the organization initiates the use of control charts and other SPC techniques to reduce variation and to improve manufacturing processes. There are some reasons why companies use SPC. Now for the final Question (f): Since 13.98 is outside our calculation of the R-bar control limits (0 – 13.53), therefore we would say that 13.98 means the process is out of control and requires investigation. To answer the Question (e): since 17.2 is within our calculation of the X-bar collection yields (11.42 – 18.8), therefore we would say that 17.2 means the process is in control which is a common cause and not special cause variations. So now, these are our upper and lower control limits for the range (the variations in this process). Let us calculate for the UCL and LCL for the R-chart in problem (c) & (d) You can see that in the middle between these two numbers you have the average of 15.11. Now, let us calculate the X-bar Chart limits from problem (a) & (b)Ī. If your data collection for the R-bar is 13.98, would the process be considered in or out of control? If your data collection for the X-bar is 17.2, would the process be considered in or out of control?į. Calculate the lower control limit for the R-chartĮ. Calculate the upper control limit for the R-chartĭ. Calculate the lower control limit for the X-bar ChartĬ. Calculate the upper control limit for the X-bar Chartī.

#Xbar equation how to#

Lets review the 6 tasks below and how to solve themĪ. Using the information below, calculate the proper control charts limits. Your plan is to sample 20 days and record the performance of 5 randomly selected workers. Your company’s stated goal is to change the oil in anyone’s automobile within 15 minutes.

#Xbar equation plus#

Since around 99.99 percent of a controlled process will take place within plus or minus three sigmas, the data from a process ought to approximate a general distribution around the mean and within the pre-defined limits.Įxample: You are setting up a statistical process control for your oil change company to determine if there is an unacceptable disparity between workers. The UCL is set three sigma levels above the mean and the LCL is set at three sigma levels below mean. In statistical process control, there is a upper control limit (UCL) and a lower control limit (LCL) set. Three sigma statistical process control methods enable business process to be manageable and stable.

The three sigma quality system is based on analysis and statistical process control (SPC). These control charts help us establish limits for business processes that require statistical control for the operations.

When we talk of statistical control using 3 sigma control limits, we use the three sigma limits to set the control limits (Lower and Upper) using statistical charts such as for example Microsoft Excel. Thisis is done by checking if data points are within three standard deviations from the mean. 3 sigma control limits is used to check data from a process and if it is within statistical control.

0 kommentar(er)

0 kommentar(er)